Zincnickel A zincnickel alloy offers greater protection against corrosion than zinc plating alone. Since bronze does not contain any iron it cannot rust.

Temperatures good surface stability and corrosion and oxidation resistance.

Metal tin alloy is rust resistant. - An alloy that exhibits excellent mechanical strength and creep resistance at high. A ferrous metal is one that contains iron and only iron can rust. Check out our selection of Corrosion Resistant Metals at IMS.

Lightweight flexible and corrosion-resistant titanium is a metal alloy used in a variety of applications from the aerospace industry to ship propellers and even dental implants and jewelry. The corrosion of tin-rich white metal bearings is rare and consequently detailed studies of the phenomenon are not extensive in the literature. Some grades of bronze contain various other metals and even non-metals such as arsenic phosphorus and silicon.

Brass is an alloy of copper zinc and other elements which also resists corrosion. Titanium is as strong as steel twice as strong as aluminum and as corrosion resistant as platinum. While convenient and initially attractive tin plating wears off and exposes the underlying iron surface to develop rust.

While convenient and initially attractive tin plating wears off and exposes the underlying iron surface to develop rust. Tin works well in many cold-working applications including spinning rolling and extruding. This category includes copper and its alloys brass and bronze.

Eventually large areas of rust form that may cause the entire metal structure to disintegrate. The 4 Best Most Corrosion-Resistant Metals for Exterior ArchitectureStainless steel steel with a chromium oxide layer that lets it shineRed metals brass copper bronze luxury metals for the fancyAluminum common in outdoor fixtures and moreMore itemsApr 15 2019. The protective coating on galvanized steel secures against deterioration and allows for both painted and non-painted applications.

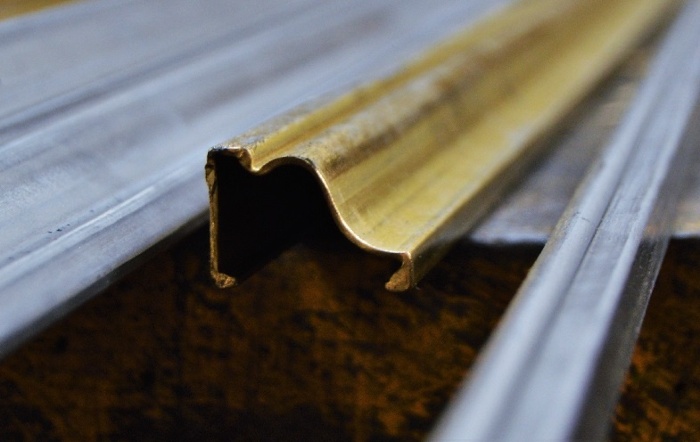

An example of an alloy is the tin in the mixture of copper and tin that makes bronze. Alloy is a metal made by combining two or more metallic elements especially to give greater strength or resistance to corrosion. The mill alloy offers excellent rolling and drawing properties with high tarnish resistance.

What metal is best for outdoor use. High-tin alloys are relatively resistant to corrosion in the organic acids that tend to be formed during the degradation of lubricating fluids and the tin salts that form have antioxidant capability. Another example of an alloy is brass which is made from copper and zinc.

Their main advantage over ferrous materials is their malleability. Galvanized steel is the least corrosion-resistant metal on this list. Despite that it is most commonly used because it offers at least 50 years of strong affordable performance 25.

High metal reusability firescale-free high fluid-ity for stone-in-place casting improved hard-ness age-hardenable and superior tarnish resistance. Grade 430 stainless steel costs less than either 304 or 316 but its corrosion resistance is not high. Today most metal roofing products are made from alloyed steel with an applied corrosion resistant coating.

When combined with other metals they can promote corrosion resistance and create alloys that offer. Today most metal roofing products are made from alloyed steel with an applied corrosion resistant coating. Additionally it provides corrosion protection for other metals when alloyed with them.

Hansen Steel has an extensive inventory of galvanized sheet metal and coils available for fast accessibility and. Other commonly used zinc alloys include zinc-iron tin-zinc and zinc-nickel. Bronze is a mixture of copper and tin along with small amounts of other elements and is naturally much more resistant to corrosion than copper.

When treated well bronze is highly resistant to corrosion. Bronze is a copper alloy typically containing around 12 tin. These are the luxury metals.

Like titanium aluminum is a base metal added to alloys to enhance machinability corrosion resistance and weight reduction. Common ferrous metals include carbon steel 1018 12L14 alloy steel 4130 and stainless steel 304 316. Copper oxidizes over time to form a green patina which actually protects the metal from further corrosion.

Galvanized steel is more about function than beauty so its not your best choice if looks matter for your project. Tinlead A tinlead alloy can reduce the occurrence of tin whiskers which are sharp metal strands that often appear after tinning and can cause significant damage to electronic components. Perhaps the most widely used alloy in zinc plating is zinc-cobalt which can increase corrosion resistance by as much as five times.

A zinc-cobalt alloy is also extremely ductile it wont lose its toughness even when deformed or bent into different shapes. They are homogeneous mixture of two or more substances. Galvanized steel is ideal for applications requiring weather corrosion and rust resistance.

In general rust and other metal corrosion can be avoided by adding alloys to a pure metal to create corrosion-resistant non-ferrous alloys along with carefully managing a metals environment. All three are readily available so go 316 if you can. Zinc most often plays a role in galvanizing steel to protect it against corrosion.

Non-ferrous metals include aluminium copper lead zinc and tin as well as precious metals like gold and silver. They also have no iron content giving them a higher resistance to rust and corrosion and making them ideal for gutters liquid pipes roofing and outdoor signs. The casting alloy features excellent and.

Galvanized steel takes a long time to rust. Corrosion resistant alloys consist of metals such as chromium cobalt nickel titanium or molybdenum. The alloys will be available in June.

Grade 304 is very durable but not as corrosion-resistant as 316. - Metallic alloys that can be used at high temperatures often in excess of 07 of their absolute melting temperature. Its also capable of withstanding higher temperatures.

The Most Corrosion Resistant Metals

No comments