It is easy to melt at 281 F and has 75 weight density of lead 03158 pounds cubic inch. Tin has nine stable isotopes and 18 unstable isotopes.

Tin Bismuth Alloy Fusible Alloy Dongguan Changan Bing Kai Metal Accessories Operating The Department Of Materials

Alloys of Bismuth and Tin have a low melting point and are non-toxic.

Bismuth tin alloy uses. The metal has a melting point lower than the polyamide and is melted and removed after. Under 372 degrees Kelvin Tin becomes a superconductor. Our environmentally friendly Bismuth-Tin alloy is becoming a popular alternative to lead for fish and other weights.

It was also used to make bismuth bronze which was used. Alloysofleadtinandbismuthmeltingabove100Chavebeen studiedratherextensivelyTheprincipalinterestinthesealloys hasbeeninconnectionwiththeiruseinautomaticsprinklersalarms releasesforfiredoorsorinothersafetydevicesVariationsincom. Tinand its alloys are commonly used as lead-free soft solder layers in the mass production of electronic components1 Small amounts of Bi 4wtare added to Sn solder to reduce whisker formation and Sn alloys with higherBicon-tents are soft solder candidates to replace tinlead2 Aqueous.

The first uses of tin can be dated to the Bronze Age around 3000 BC in which tin and copper were combined to make the alloy bronze. As replacement for lead materials like silver tin copper zinc antimony bismuth and indium have been studied. Bismuth Tin alloy is environmentally friendly material.

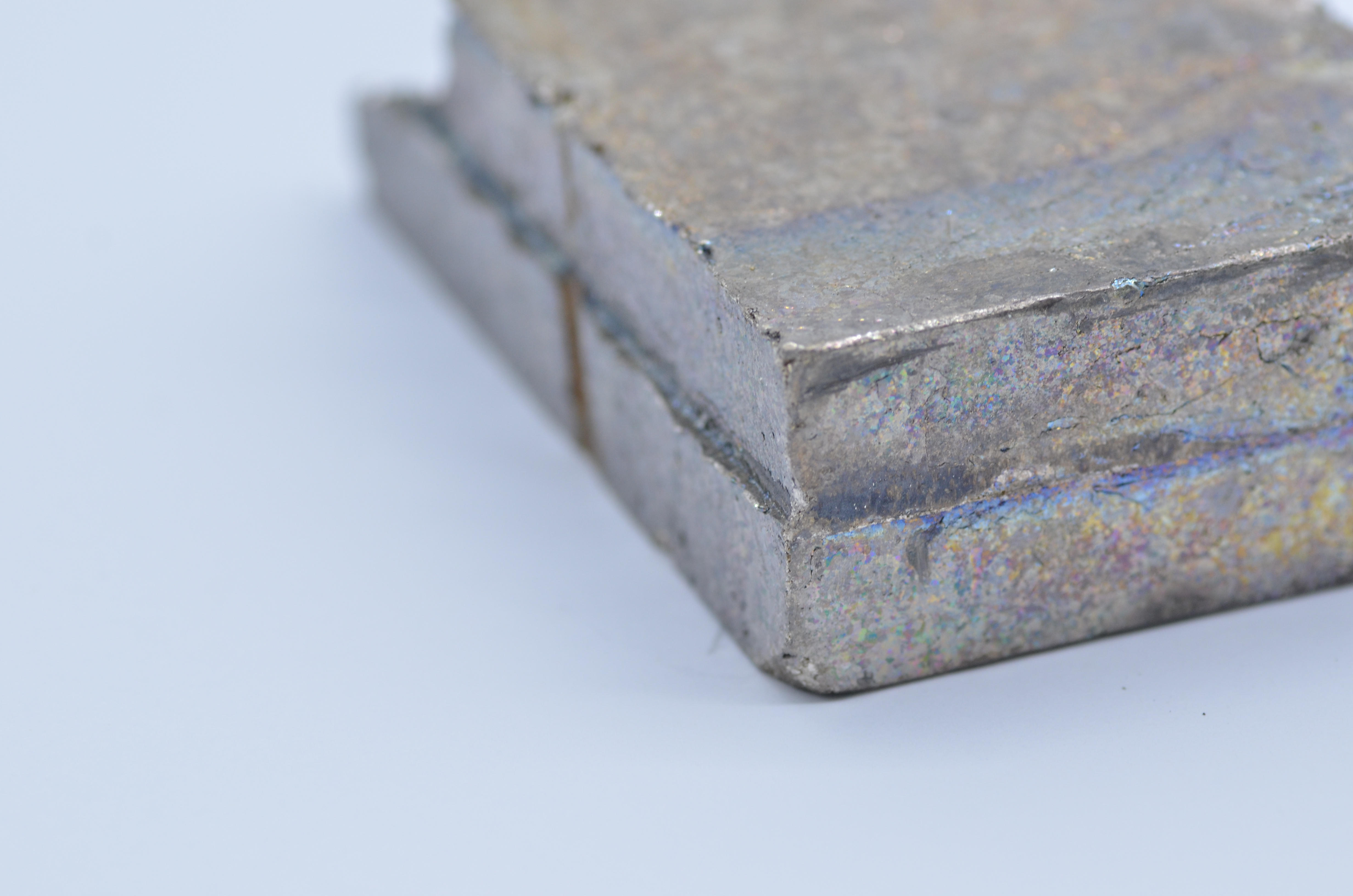

It has a rhombohedral Biα structure with an atomic radius of 154 Å electronegativity of 183 and valence of 3 and 5. The alloy is 58 Bismuth and 42 Tin. It is commonly used as an alloying element for various low melting alloys where it is mixed with other metals such as Lead Tin or Cadmium.

These alloys are used in automatic sprinkler systems for fires. When a bar of tin is bent the so-called tin cry can be heard as a result of sliding tin crystals reforming. Bismuth is most often used to make lead-free solder and glazes for ceramics.

This trait is shared by indium cadmium and frozen mercury. First experiments to determine the wetting properties of the Sn-Bi solder are presented. Many companies have evaluated this alloy with much of.

This article presents an overview of these issues. Sino santech materials is a manufacturer of bismuth tin alloy in forms of lump ingot bar wire and powder. Tin-bismuth alloys may be an alternative to lead-based solders for low-temperature applications but very little is known about their manufacturability and reliability.

Tin is a soft malleable ductile and highly crystalline silvery-white metal. 37 Among the candidate lead-free alloys eutectic tin-bismuth alloys have specific advantages including low melting point low Youngs modulus and low thermal conductivity as indicated in Table I. This is an alloy we have been asked to make a few times so we decided to make a larger batch and have it easily available to everyone.

Tin like indium is soft enough to be cut without much force. They are an ideal material for students to practice casting techniques and form-making being non-toxic and entirely re-useable. In 1980 Dunlop developed a unique injection moulding process used for their popular Max 200G.

The origin of the word tin comes from the Latin word Stannum which translates to the Anglo-Saxon word tin. Sliding bearing alloy contains in weight. Potential Health Dangers While bismuth has been regarded as a safe alternative to lead there is still the potential for exposure and harm.

The baths find particular use in electrodepositing eutectic compositions such as 58 Bi-42 Sn. It forms the largest part 50 of Roses metal a fusible alloy which also contains 2528 lead and 2225 tin. The hollow racket frame consisted of Polyamide 66 with carbon fibre reinforcements.

Bismuth core bullets are also starting to appear for use in indoor shooting ranges where fine particles of lead from bullets impacting. Why Companies Are Switching from Lead to Bismuth for Their Copper and Tin Alloys The use of lead in manufacturing is being increasingly regulated due to the fact that lead is a toxic heavy metal. Its also been tested for use as ball bearings but bismuth alloyed bearings appear to have poor fatigue resistance and are prone to failure.

More specifically we will investigate the BiSnAg alloy with a composition of 57Bi42Sn1Ag. Applications for tin include soldering plating and such alloys as pewter. 89 The lower melting point facilitates lower joining temperatures the low Youngs.

Soluble bismuth anodes are used to replenish bismuth in the bath solution. Lead is no longer allowed for use. Bismuth is used in metal alloys with other metals such as iron.

SDS Lead Free Fishing Tackle. Baths are disclosed for electrodepositing bismuth-tin alloys of all ratios as shown by the Figure. The bismuth gives you the weight as close to lead as possible and the tin helps holds it together and makes it less brittle.

Bismuth is a low cost alloying option especially in light of rising metals costs and will be considered in this paper. Bismuth is used as catalyst in the production of plastics and cosmetics as additives in steel alloys aluminum and in electronics. One ingot weighs approximately 1 pound.

Bismuth compounds are also used as a pigment in certain cosmetics and some pharmaceuticals for digestive problems such as bismuth subsalicylate. They are being used as a low-temperature casting alloy especially for educational purposes. Bismuth-tin alloy shot is one alternative that provides similar ballistic performance to lead.

So I decided on the Bismuth-Tin alloy because of its low melting point since we actually have to use the equipment we have in our lab to conduct experiments and test the properties or otherwise make the things the problem is that I havent found any applications for this alloy neither can I find any information about it on the interwebs. When a bar of tin is bent a crackling sound known as the tin cry can be heard from the twinning of. Tin Bismuth is one of numerous metal alloys sold by American Elements under the trade name AE Alloys.

Tin Bismuth powder is used in thick film solder coatings. The eutectic alloy is 46 Bismuth and 54 Tin by wt. To manufacture the hollow frame a bismuth-tin alloy was used as its core.

It is easy to melt at 281 F and has 75 weight density of lead 03158 pounds cubic inch. Another less expensive but also more poorly performing alternative is steel shot which is actually soft iron. Lead-free alloys eutectic tin-bismuth alloys have specific advantages including low melting point low Youngs modulus and low thermal conductivityasindicatedinTableI89 Thelowermeltingpointfacili-tates lower joining temperatures the low Youngs modulus allows for.

Bismuth is a white brittle metal with a slight pink color and is typically recovered as a by-product of lead and copper. DE10145389A1 - Alloy used in the manufacture of sliding bearings for electric motors contains antimony copper bismuth indium and tin - Google Patents.

No comments